1. Load-bearing Capacity

Material Selection Based on Product Characteristics: Firstly, it is crucial to determine the weight, shape, and size of the product that the paper bag needs to carry. Different paper bag materials have different load-bearing capacities, such as white cardboard, Kraft Paper , etc. Choosing the appropriate paper bag material based on product characteristics is vital.

Fine Workmanship: Apart from material selection, the workmanship of the paper bag is also a crucial factor affecting its load-bearing capacity. Ensure that the stitching or bonding of key areas such as the bottom, sides, and handles is secure to withstand the product's weight.

2. Color and Design

Aesthetically Pleasing and Elegant: The color combination should be aesthetically pleasing and elegant, aligning with the product's brand image and market positioning. At the same time, the design should be simple and clear, easy to identify, avoiding overly complex or flashy designs that affect visual appeal.

Consistency with Brand Tone: The design of the paper bag should be consistent with the brand image and tone, enhancing brand recognition and consumer favorability.

3. Sense of Quality

Material Choice: High-end paper bags typically choose high-quality, comfortable-to-touch paper materials, such as white cardboard, specialty paper, etc. These materials not only enhance the sense of quality of the paper bag but also provide a better user experience for consumers.

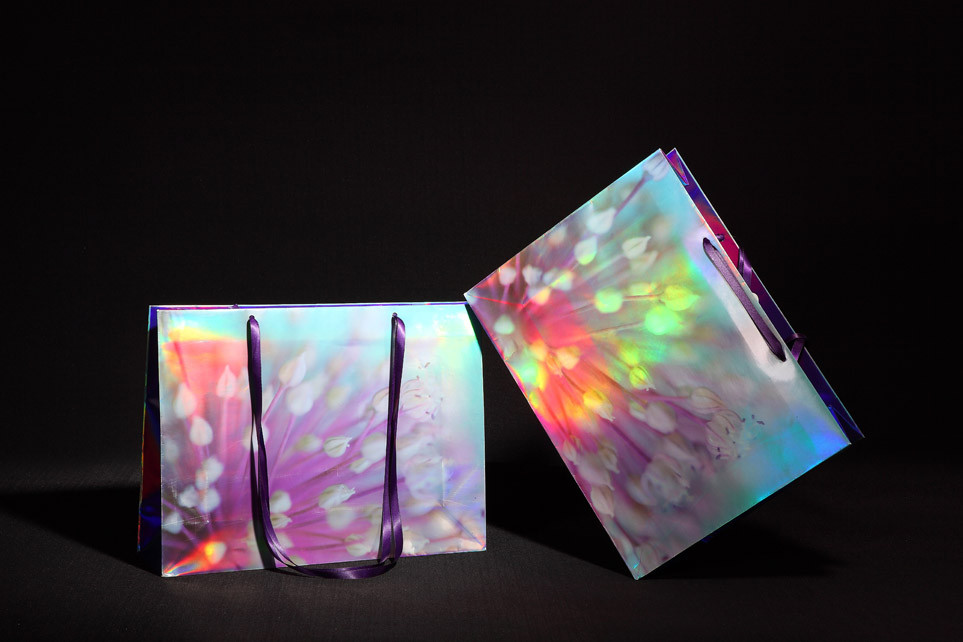

Design and Craftsmanship: The design should be novel and unique, attracting consumers' attention; the craftsmanship should be meticulous and well-considered, ensuring that every detail is perfect. For example, gold or silver foil stamping can enhance the sense of quality and texture of the paper bag.

4. Surface Treatment

Suitability: The surface treatment process should be selected based on the material and purpose of the paper bag. For instance, coating can improve the water and moisture resistance of the paper bag; laminating can enhance its abrasion resistance and tear strength.

Optimal Effect: When choosing a surface treatment process, ensure that it showcases the best visual effects and performance. Avoid over-processing or improper processing that leads to a decrease in paper bag quality or an increase in cost.

5. Cost Control

Reasonable Budget: When customizing packaging paper bags, it is essential to formulate a reasonable cost control plan based on the budget. While ensuring quality and effect, try to reduce material, labor, and other costs.

Cost-effectiveness Consideration: Pay attention to cost-effectiveness considerations in material selection and process treatment, avoiding blindly pursuing high-end materials or complex processes that result in excessively high costs.

6. Flexible Material Usage

Customization According to Needs: Flexibly adjust the size, shape, and capacity of the paper bag according to actual needs. Avoid excessive waste or insufficiency in meeting product packaging requirements.

Eco-friendly Concept: When customizing packaging paper bags, it is also important to emphasize the application of eco-friendly concepts. Choose degradable, recyclable, and environmentally friendly materials; optimize production processes to reduce waste generation; and promote the use of eco-friendly packaging concepts.

In summary, custom packaging paper bags requires considering multiple aspects such as load-bearing capacity, color and design, sense of quality, surface treatment, cost control, and flexible material usage. By comprehensively considering these factors, we can ensure that the quality and suitability of the final product meet market demands.

Post time: Sep-26-2024